Digitalisation: a framework for high hazard industries

Society struggles to encapsulate and articulate the biggest revolution of our time with clunky buzzword phrases such as ‘The Second Machine Age’, ‘The New Digital Industrial Revolution’ and ‘Industry Revision 4.0’. Perhaps this is because ‘digitalisation’ is becoming so extensive, pervasive and ubiquitous, it has the potential to effect almost everything, everywhere. So what is it and what does it mean for the high hazard industries?

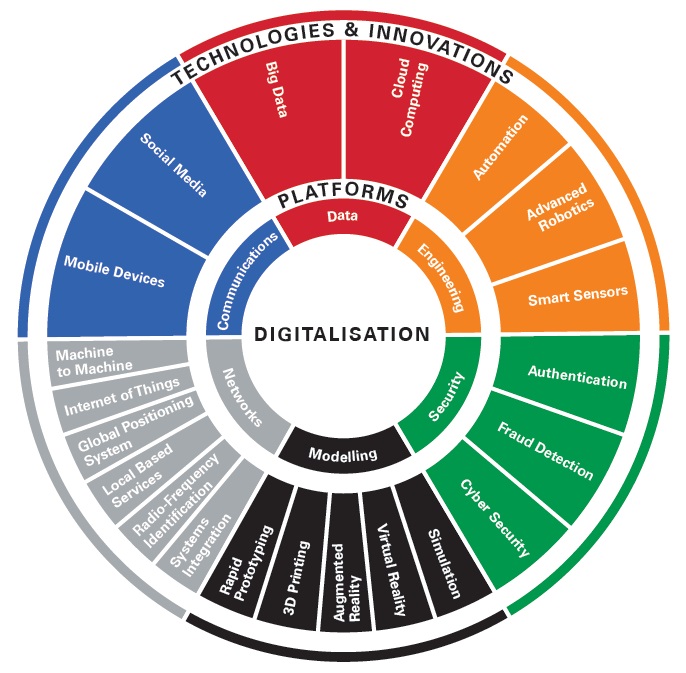

Whereas ‘digitisation’ is the process of converting information into a digital format, ‘digitalisation’ is the integration of digital technologies into everyday life by digitising everything that can be digitised. Digitalisation, if used appropriately, can make things easier, more efficient, faster, cheaper, more accessible, more visible, more user friendly, simpler, more reliable, safer, more secure, more realistic, more enjoyable and so on.

The opportunities are pretty much endless and only really limited by our imaginations. So, no wonder it is difficult to encapsulate and articulate.

OPPORTUNITIES…

Whilst businesses can choose to ignore digitalisation at their commercial peril, this is not an option for high hazard industries. Even if they wanted to overlook the opportunities to improve and optimise business performance, they must embrace the opportunities to directly reduce risk. They have a responsibility to ensure they maintain their risks as low as reasonably practicable (ALARP) by embracing all reasonably practicable opportunities that come along. Digitalisation presents a range of such opportunities, for example:

- Advanced robotics could completely remove operators, maintainers and inspectors from potential hazards thereby eliminating risk to people.

- ‘Big data’ (allowing vast quantities of complex data to be processed and analysed extremely quickly) coupled with artificial intelligence could allow active condition monitoring systems to directly control operations, creating a self-policing system that is quicker, more responsive and hence safer than conventional human controlled systems.

- Virtual and augmented reality allows operators to practice safety critical roles and rehearse emergency response scenarios in a highly realistic and immersive way. This makes them more prepared, resilient and competent to perform these roles.

…AND THREATS

As with any change, despite good intentions, if inadequately conceived or executed, digitalisation could compromise overall safety. Such potential threats include:

- Unexpected or erroneous system responses caused by poor design of software or bugs, or virus attacks.

- Malicious operation of safety critical systems by hacking of cyber systems, such as big data and cloud computing.

- Inability of smart sensors to achieve the reliability targets required to meet their safety function, thus compromising overall safety integrity.

- Not addressing whether the outcomes of automated decisions will be decided by ethics or data. For example, in a critical situation, should automated machinery be programmed to damage a safety system if necessary to avoid harming a worker?

MEASURE TWICE, CUT ONCE

You can only manage the risks you know about; so, before introducing digitalisation, high hazard industries must appreciate fully the potential threats associated with each change. This can only be achieved through a fundamental understanding of the specific innovation and what it does for operations and safety. This means:

- Understand what digitalisation actually is. Figure 1 presents a helpful framework to work through.

- Translate this language into terms that designers, operators and managers of facilities can understand and relate to. This challenge should not be underestimated. Those at the forefront of digitalisation generally have very different backgrounds and outlooks from those involved in the more conservative industrial sectors.

- Apply this understanding to identify what opportunities digitalisation presents and what the associated threats may be.

MANAGING CHANGE

From this point onwards embracing digitalisation is about change management and standard risk management processes apply. This involves identifying the hazards introduced during implementation and subsequent operation, as well as those measures that can be put in place to ensure that the associated risks are reduced ALARP. As noted above, one key break from the status quo will be the need for relevant digitalisation expertise to bridge the language barrier. Digitalisation skills will surely become central to high hazard industry competence frameworks in the not too distant future.

It would be a mistake to view digitalisation as a one-off activity. By its very nature it is a fast moving landscape with new developments, breakthroughs and applications happening all the time. High hazard industries should embrace these when the time and opportunity is right. This implies both regular and adhoc reviews to keep up to date with general developments and to react to major, ground-breaking innovations.

CONCLUSION

Digitalisation is intended to make life easier and is becoming integrated into everything we do in a seemingly relentless series of technological advances. In doing so, it presents a new challenge for high hazard industries. But, armed with a detailed understanding of what digitalisation means and a robust risk management process, this is a challenge that can be readily overcome, reaping the benefits.

This article first appeared in RISKworld issue 32