Preventing ‘sub-prime safety’

There are many parallels between the causes of the current credit crisis in the financial markets and the causes of major accidents in high risk industries. These include ineffective leadership, weak management systems and a ‘profit at all costs’ culture, as well as a lack of understanding of the underlying technical risks and their inter-dependencies.

LEADING FROM THE TOP

So how should organisations prevent ‘sub-prime safety’? A recent UK HSE conference “Leading from the Top” involving CEOs, industry leaders, regulatory bodies, unions and government ministers, defined seven key elements (see Box 1) for effective safety risk management [Ref. 1].

UNDERSTANDING RISK SCENARIOS AND THEIR CONTROLS

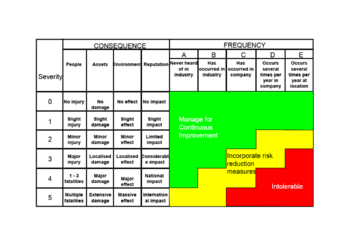

To allow all levels of an organisation to play their part, clear accountabilities should be defined and everyone should understand the risks faced and their role in controlling those risks. Whilst complex risk assessments have their place, it is questionable whether the comprehension of a numerical quantification of risks is necessary at the board level or at the work site.

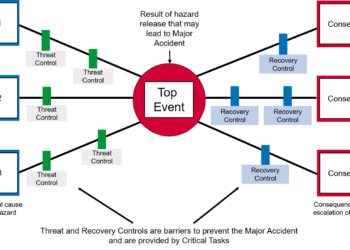

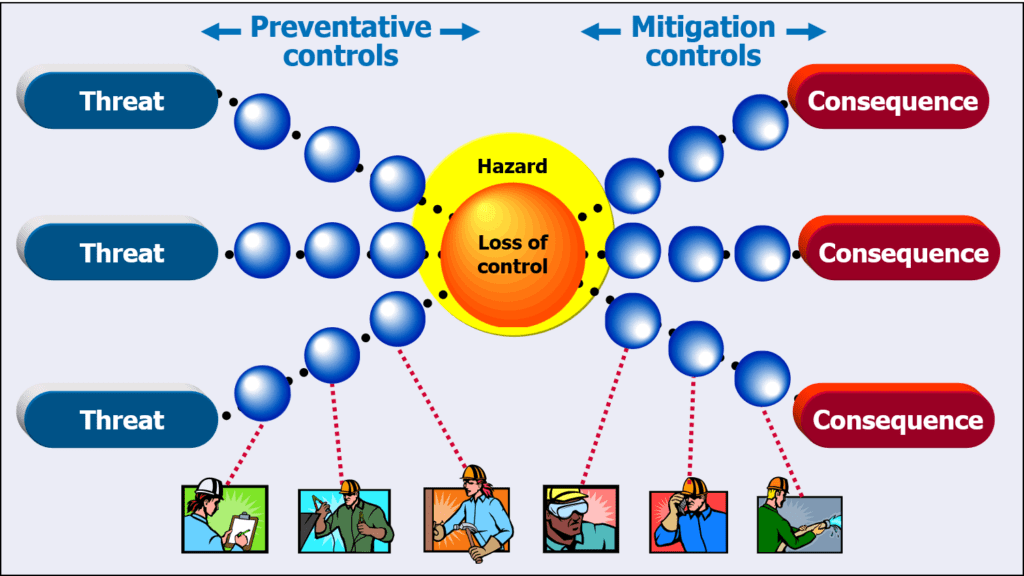

Risk assessments must always be fit for purpose. Tools such as bow-ties [Ref. 2] have been proven time and again to remove the mystique from risk management and allow people to focus on what really matters (see Fig. 1).

Figure 1 – The bow-tie method: helping to ensure that risks are managed rather than just analysed

The simple graphical format allows for immediate understanding of the complete picture – the causes and consequences of business upsets and how these are prevented and mitigated. In this sense it is true that “a picture paints a thousand words”.

REALLY UNDERSTANDING CONTROLS

Every control should be closely examined by the organisation to confirm its effectiveness. Typical areas of uncertainty may include:

- Does the control actually exist and work as intended, e.g. level switches at Buncefield?

- Are responsibilities for the control clearly defined, e.g. permit-to-work at Piper Alpha?

- Will the control continue to work in the future, e.g. O-rings on Challenger space shuttle?

- Is supporting documentation in place, sufficient, controlled and available, e.g. management of change at Flixborough?

- Is the level of control suitable and sufficient, e.g. safety systems at Bhopal?

Such questioning of the risk controls provides for a thorough, transparent review of the risk management process. It not only establishes a snapshot today, but also ensures control is maintained for the future. This approach also provides a benchmark against which change can be reviewed, whether to hardware, the organisation, or to personnel.

Identifying the jobs that are critical to implementing the controls highlights the need for the personnel doing those jobs to be well trained and competent to fulfil their roles. This direct link between risk control and personal responsibilities promotes understanding and ownership and can be further enhanced by the use of competency management systems such as Skills XP [Ref. 3]. Reviewing the bow-tie controls against incidents occurring within the organisation and also externally, allows valuable lessons to be learnt as to whether the overall risk control is weak or could be further improved.

CONCLUSION

Following the investigation into the Texas City refinery explosion, the safety review panel concluded [Ref. 4], “We are under no illusion that deficiencies in process safety culture, management, or corporate oversight are limited to BP. Other companies and their stakeholders can benefit from our work.” Similarly, the lessons of the sub-prime mortgage crisis apply to all of us, irrespective of industry.

Bow-ties are not a panacea for all risk management problems, but their spread across companies, industries, countries and from industry to regulator is not surprising given the power of the approach. What’s more, their application can embrace all risks, whether safety or financial.

Risktec regularly runs a masterclass in the application of the bow-tie method.

References

1. Leading from the Top – Avoiding Major Incidents, Apr-08, http://www.hse.gov.uk/ leadership/mhconference.htm

2. RISKworld Issue 6, Autumn 2004.

3. RISKworld Issue 8, Autumn 2005.

4. Report of the BP US Refineries Independent Safety Review Panel, January 2007.

This article first appeared in RISKworld Issue 14.