Remote Inspection – The arrival of the virtual expert

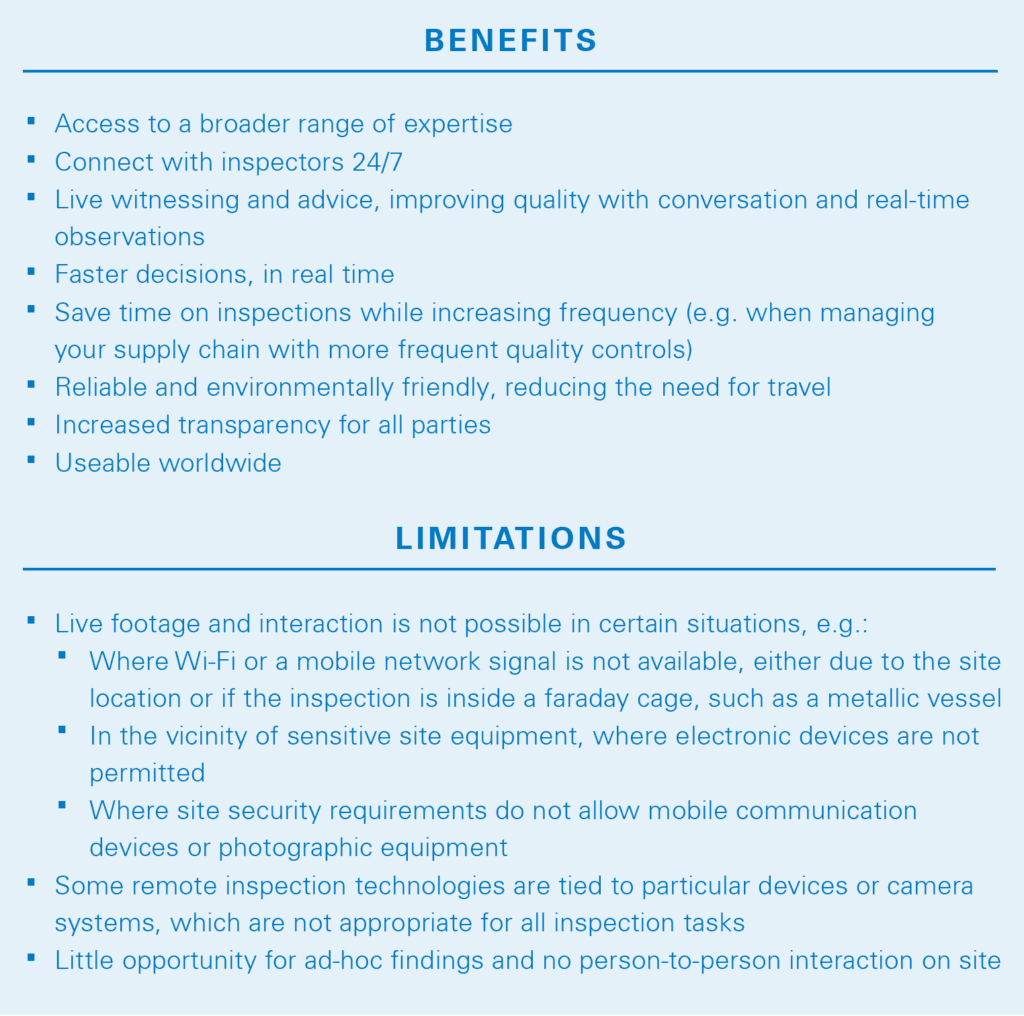

The capabilities of modern camera and communication technologies have enabled the creation of a new team member – the virtual expert – who is able to support you with remote inspection and assessment services at any time, regardless of your location. But how does it work, and what are the benefits and limitations?

© TÜV Rheinland

WHAT IS REMOTE INSPECTION?

In some ways, remote inspection is not a new technique – since the advent of digital photography it has been easy for personnel at, for example, a factory or an offshore oil platform to send images and supporting information to offsite experts and other stakeholders when seeking advice or approval.

The quality and speed of such interactions can, however, be limited by the experience of the person capturing the images, especially if they are working on a topic they are not familiar with. Consequently, site visits are normally still required to get to the bottom of an issue.

Recent advances in imaging and communications technology have enabled a step-change in the way remote inspections and assessment can be delivered. Now, site personnel can interact with their offsite ‘virtual’ expert live, conveying images and video from the point of inspection. This allows the inspection to be directed and discussed as it happens, ensuring that relevant information is captured first time and obviating the need for a site visit.

APPLICATIONS

Remote inspections can be used to conduct a range of tasks, such as:

- General site inspection, e.g. virtual audit

- Inspection and assessment of specific components, e.g. during manufacture, fabrication or in-service

- Reducing the risk to personnel when witnessing tests, e.g. over-speed or pressure test

- Reducing the safety risk associated with working at height, below grade or in confined spaces by using robotic inspection equipment

- Outage, turnaround and maintenance planning activities

- Monitoring equipment for in-service movement or leaks

Using a virtual expert, such inspections can also result in significant cost savings when compared to the conventional approach, while still benefiting from the value-adding nature of good advice, for example where:

- The expert and the items to be inspected are in different geographical locations

- Specialist skills or qualifications are needed to access the location to be inspected

- There is a practical or risk management need to minimise the number of personnel present at the point of inspection

© Shutterstock

CHOOSING THE RIGHT SYSTEM

A variety of remote inspection providers are now available. Some offer a ‘closed-loop’ approach, where the supplier controls all of the software and hardware in their ecosystem. Others take a more open attitude, providing the system to enable the inspections, but allowing the inspections themselves to be captured using any appropriate device, such as a mobile phone, tablet, set of smart glasses or even drones or mobile service robots.

When choosing a system, it is important to ensure that the equipment is appropriate for the types of inspections that are required. For example, would the defects the inspector is looking for be visible? For the identification of cracking, a high resolution image is required, so the camera on a set of smart glasses may not be adequate. For items that can only be viewed from a distance, such as when monitoring corrosion on a wind turbine tower flange, the zoom function on a tablet or mobile phone is unlikely to be sufficient and a drone might be required.

CAUTIONARY NOTES

Use of remote inspection equipment can also introduce additional safety risks which must be identified and managed, for instance:

- When inspecting areas with potentially flammable or explosive atmospheres, ATEX-rated equipment must be used

- Smart glasses may interfere with the user’s ability to wear their safety glasses and helmets, or restrict vision, increasing the risk of slips, trips and falls

Remote inspection necessarily involves the transmission of data that may be sensitive. Care must be taken to ensure that appropriate encryption and authentication steps are put in place, or are inherently part of a supplier’s system, so that data security is maintained.

CONCLUSION

The advent of remote inspection technology, combined with virtual experts, makes it quicker, easier and cheaper to survey and diagnose issues, supporting effective decision-making and improving the quality of operations. But care must be taken to ensure that the task, equipment and personnel are compatible with the objectives of the inspection.