Precisely right: an introduction to vendor inspection

Procuring new equipment for a large industrial project such as an oil, gas or petrochemical facility inevitably involves a complex supply chain. Manufacturers of equipment like valves, pumps, piping and control systems can be located across many countries and even continents. So what is the most cost-effective way to confirm product quality and compliance with specifications?

Image © TÜV Rheinland

Whether the equipment is being bought directly by the operator of the facility or via the engineering contractor, what is required is for it to be delivered to site on-time, to the specified quality and safety performance, while complying with all relevant local and international standards.

It is therefore no surprise that such equipment procurement needs to be managed in a way that minimises both project and operational risk. This is where vendor inspection steps in to help.

WHAT IS VENDOR INSPECTION?

Vendor inspection is used by operators and contractors when purchasing equipment either for a new capital project, which involves buying a lot of equipment, or for maintenance and upgrades of an operational facility where fewer items are required.

Vendor inspection of the equipment can take place along the whole supply chain:

- During the manufacturing process

- Prior to the equipment leaving the manufacturing site (‘pre-shipment’)

- On arrival at the final site (‘postshipment’)

- After installation

Clearly, the earlier the inspection is carried out the greater the opportunity to correct any faults and avoid unnecessary re-work costs and delays.

WHAT IS ACTUALLY INSPECTED?

As there is no statutory requirement to carry out vendor inspection, it is the purchaser who sets the level of the inspection depending upon their strategies for quality and risk control. On occasion, a bank may stipulate that vendor inspection is necessary to meet funding conditions. The requirements are normally captured in the purchaser’s quality plan or inspection and test plan (ITP).

Ideally, vendor inspection would cover full inspection of all equipment at the manufacturing site. For a valve, as an example, this might include inspection of the casting, material checks, witnessing of the pressure tests and functional tests, dimensional checks, and review of the painting, packing and shipping arrangements.

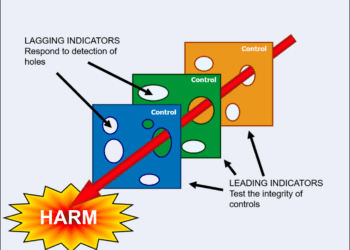

Some purchasers will take a riskbased approach to determining what inspections they require, whilst others will request the expertise of an experienced third-party inspection company to advise them of the scope. Operators who are using riskbased inspection (RBI) to optimise inspection schedules for their operational assets will normally take a risk-based approach to procurement as well.

However, some purchasers will simply opt for a final inspection and hope that this will ensure that the equipment will be correct. Others may not undertake any inspection at all, thus saving the cost of inspection, but tacitly living with the downstream operational risk.

The extent of implementation of vendor inspection across high hazard sectors varies, although most of the larger international operators in the oil and gas sector do have such programmes. There is some vendor inspection in the power, energy and transportation sectors and it is starting to become more prevalent in renewables. On occasion it is found in the chemical and pharmaceutical sectors.

HOW IS THE INSPECTION CARRIED OUT?

Whatever inspection technique is used – visual, witnessing of tests, measurement, etc. – an inspector needs to be present at the manufacturing site, often at short notice. A large capital project might have equipment suppliers located all around the world, which is why most purchasers will use one of the leading, global suppliers of vendor inspection. They will have inspectors in most countries, usually close to suppliers, and the best will have a software system to enable the efficient allocation and coordination of competent inspectors for the inspection assignments.

WHAT ARE THE BENEFITS?

Vendor inspection aims to identify any technical issues prior to the equipment arriving on site. If the equipment arrives and is outside the original specification it can have a significant impact in terms of delay to the construction schedule or shutdown period, and can also have negative safety and environmental implications, ultimately disrupting production output.

The main benefits of vendor inspection may be summarised as:

- Full transparency of the quality of procured equipment

- Documentation of the quality of goods and manufacturing processes

- Confidence in vendor and subcontractor compliance with applicable standards

- Improved reliability and competitiveness by identifying bottlenecks and weaknesses in the supply chain

- Early action to avoid delays and increased project costs

CONCLUSION

The most cost-effective way to confirm product quality and compliance with specifications is to conduct inspections at the site of manufacture. Inspectors verify that the equipment ordered complies with the specification and expectations of the purchaser, taking into consideration industry standards and regulations. A risk-based vendor inspection programme can focus inspections where they are most needed to help mitigate cost, schedule, safety, environment, production and regulatory risks.

This article first appeared in RISKworld issue 33